Panoramic

Ultra-clear display of the entire dental arch and jawbone structure.

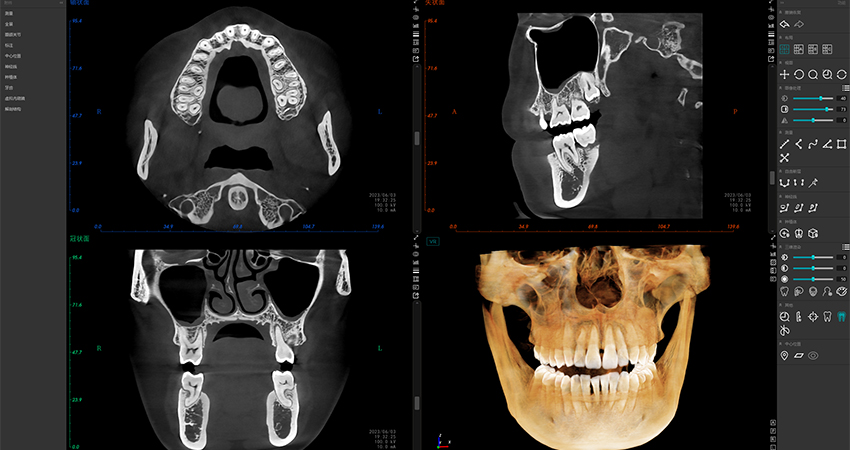

CBCT

Clear display of human craniofacial 3D anatomical structure.

Ceph

Effortlessly obtain high grayscale, high-resolution cranial standard/lateral images.

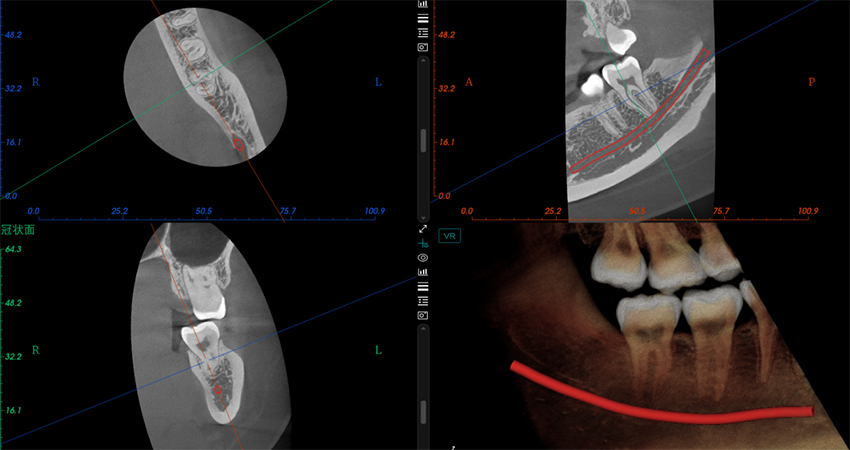

Endo Mode

Configured with high-speed, high-resolution 80μm part CT.

Imaging Algorithms

PD (Pure-Detail) Technology

Through adaptive capability, it intelligently adjusts various parameters and, based on extensive imaging results, enables the images to exhibit a "natural texture" effect. This effectively solves the problem of noise reduction effect masking tiny lesions, providing clearer restoration of bone and soft tissue structural details.

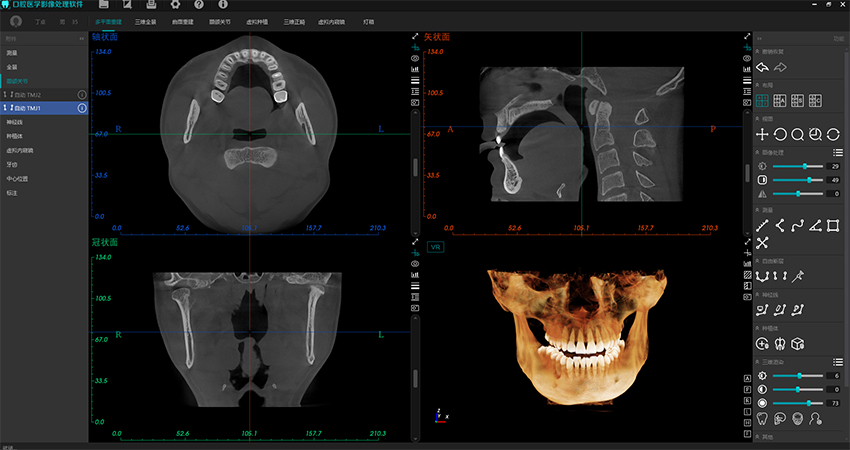

Software

The leading 3D diagnostic software and intelligent orthodontic analysis system from Meyer are designed with a modular UI, making the software functions closer to clinical diagnosis and treatment needs, and more aligned with the operating habits of Chinese doctors, with lower learning costs.

Meyer 3D Diagnostic Software (MyDent Viewer 3D)

Provides a rich and convenient clinical diagnostic toolkit, including multi-plane reconstruction, 3D panoramic imaging, surface reconstruction, virtual implantation, TMJ joint analysis, 3D orthodontics, and virtual endoscopy, greatly enhancing doctors' diagnostic efficiency.

More Highlights

| Engineered Design | Rigorous Component Selection | Intelligent Manufacturing |

| Engineering design features a highly modular and standardized structure of the entire machine, changing the traditional manufacturing model. | The selection of components and a systematic inspection system are ensured for quality control. | The creation of a smart factory, with components produced through automation and intelligent processes, and the whole machine assembled via flexible automation, significantly enhances product reliability. |

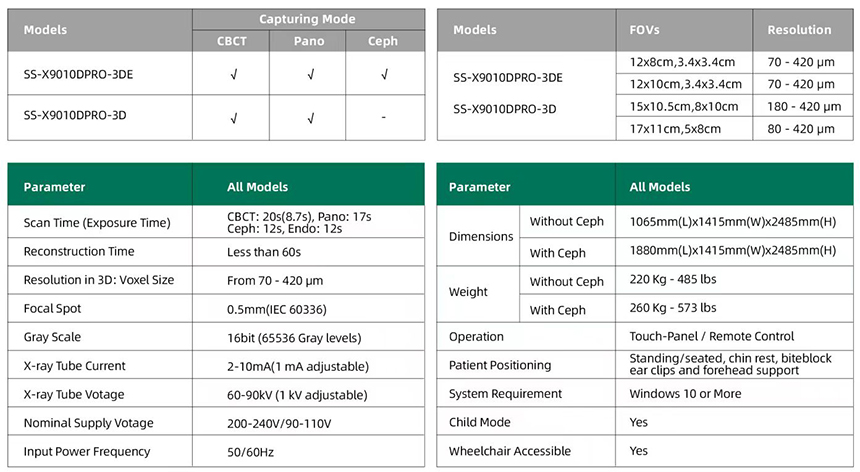

Specifications

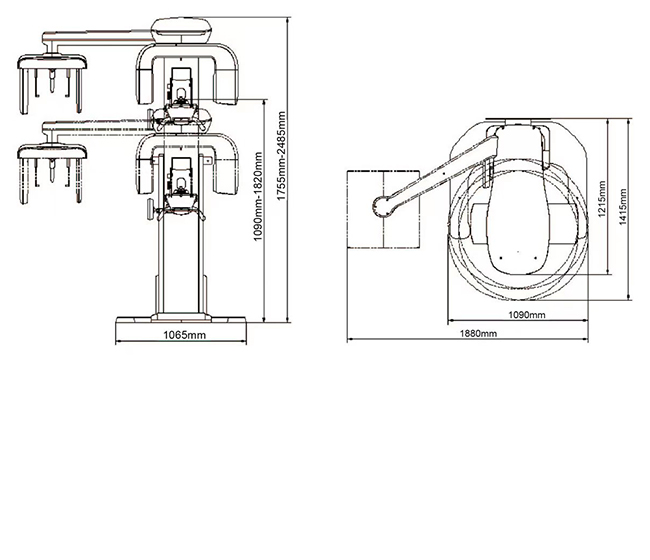

|

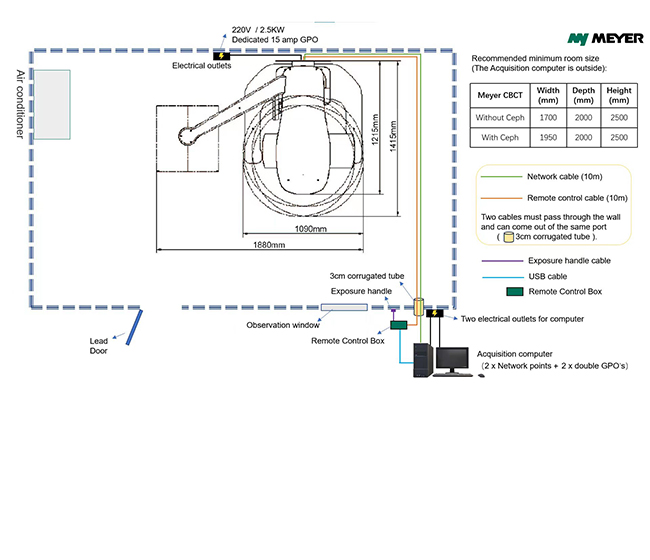

|

| Dimensional Diagram | Lead-lined Room Diagram |